Back to trash hacking main index

Not like software.

Two big differences between hacking on computers and trash hacking: One, It

is somewhat less than trivial to create another "instance" of something,

and two, it is somewhat easier to wreck things permanantly. These are

pictures from inside components that are very hard to take apart without

wrecking, most of which I, yes, did wreck. They are provided so you don't

have to make the same sacrifice I did.

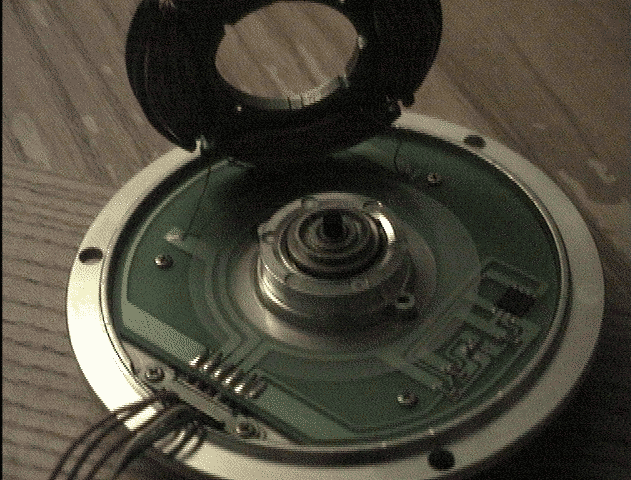

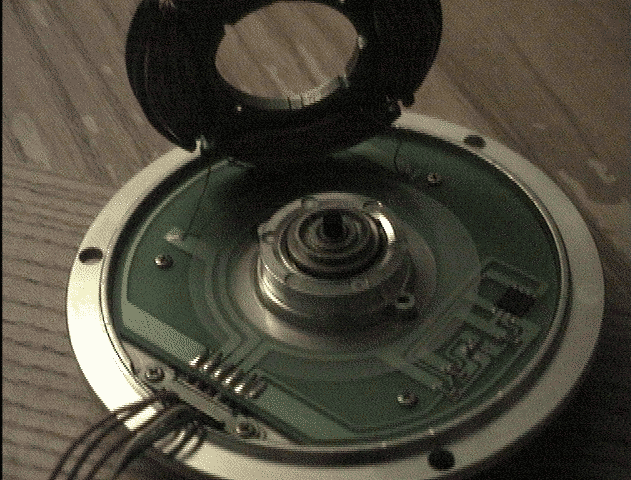

The inside of one type of platter motor from the old Seagate MFM/RLL drives

(Nidec 900552ish.) Getting the flywheel/rotor magnet off the bearing will

likely bend it. The four-contact surface mount component I accidentally

pried off along with it was black with either an Ohm symbol or a "C1" written

on it, I can't tell. I think the 8-contact chip is the Hall sensor -- it

reads "dG" on the front and "6393-8F4" on the back. Anyway you can see the

coil wires are pink, red, and brown and nothing else is in series or

parallel. It's a two-phase motor (brown is ground.) Oh well, that makes

one more ugly fridge magnet.

Unfortunately it's been so long I lost track which motor this board belongs

to, but I'm sure I'll run across one again sometime. As is common, the

center tap of the Y coil wiring is soldered to the board but not traced to

any of the connectors. But at least nothing is in series or parrallel with the

U/V/W coil ends.

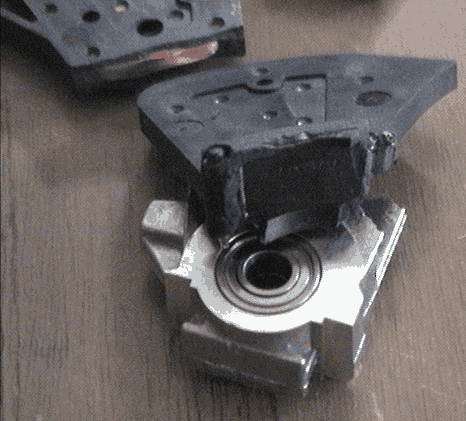

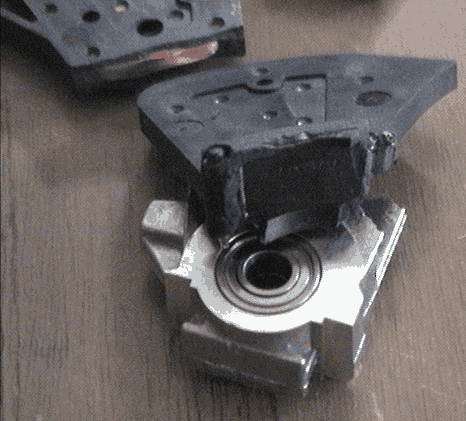

Getting the voice coil off a Quantum armature with the contact pins still

attached pretty much requires you melt the plastic in a certain point on both

sides. I've only gotten one off intact so far. Here's a picture of a failed

attempt so you can see how the metal lip runs. From the steel pins that the

ribbon cable attaches to, extremely fine coil wire run directly through the

plastic to the coil, so once it's broken (and the plastic is fairly brittle)

the only way to make a contact is to shave the area smooth, find the cable

(which may require a magnifying glass,) drop a solder bead on it and hope.

That's a chore worth avoiding.

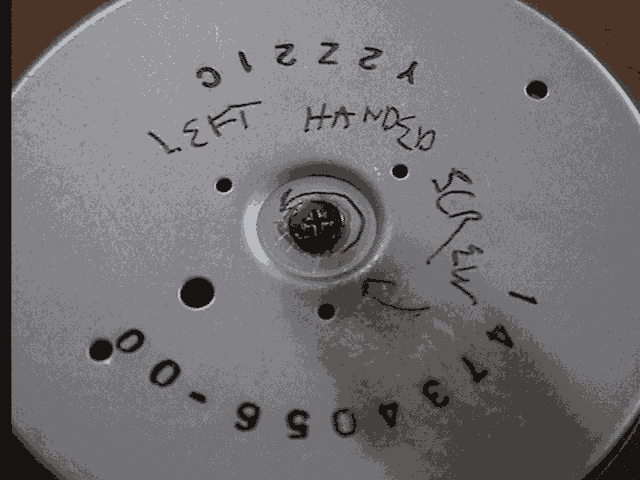

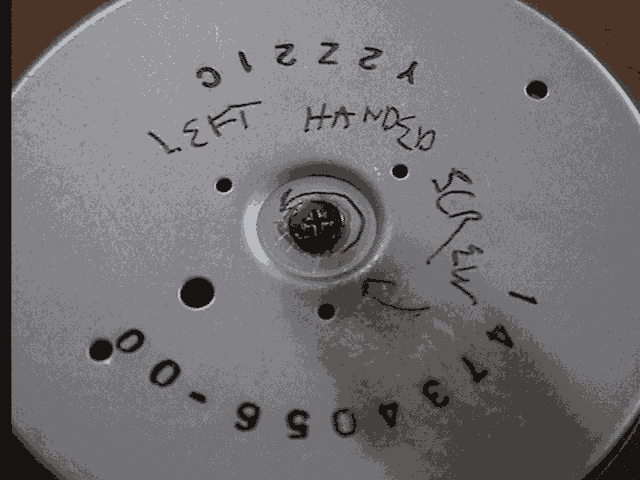

Beware the floppy-drive motor infamous left-handed screw. Floppy motor screws

are extremely hard to get out because they are glued in pretty heavily, so

it's extremely annoying that, on top of that problem, a good number of floppy

drive center spindle screws are left-threaded. This means if they are

drilled out after being stripped, good luck finding a replacement. Before

trying a screwdriver, because even those rare ones that fit still seem to strip

the bolt, I have had some luck with this: I clean enough of the guts from

the other side of the floppy so I can get a firm grasp of the plastic

disk that rotates with the flywheel. Then I try to rotate the two

independently, which will sometimes take the whole thing apart, but at the very

least, it helps break any glue between the screw and the flyweel.

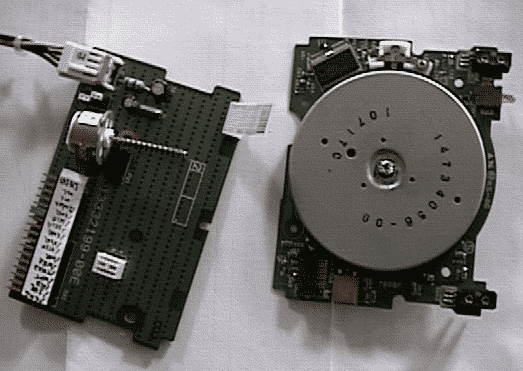

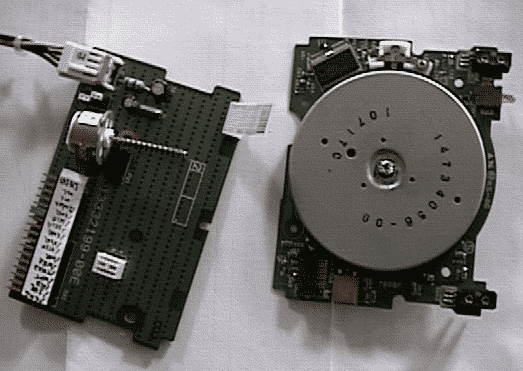

Once you've got the disk off you can get the circuit board off and you are

well on your way to the old-hat trick of hacking the floppy motor into some

sort of robotics device.

Once you've got the disk off you can get the circuit board off and you are

well on your way to the old-hat trick of hacking the floppy motor into some

sort of robotics device.

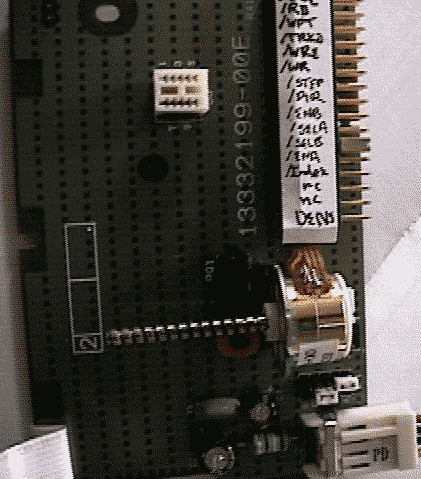

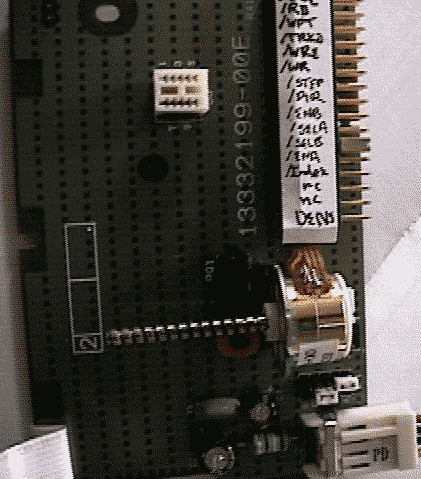

This shows just how easy that is with 3.5" floppies. Since the bottom row

of pins is grounded, just put a jumper across the inputs you want permanently

pulled low. For more on hacking floppies, see the

SunFlopper page.

This shows just how easy that is with 3.5" floppies. Since the bottom row

of pins is grounded, just put a jumper across the inputs you want permanently

pulled low. For more on hacking floppies, see the

SunFlopper page.

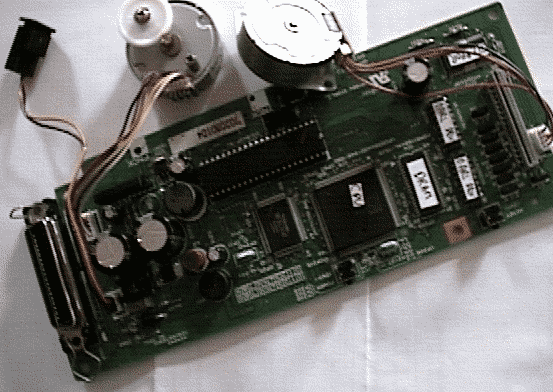

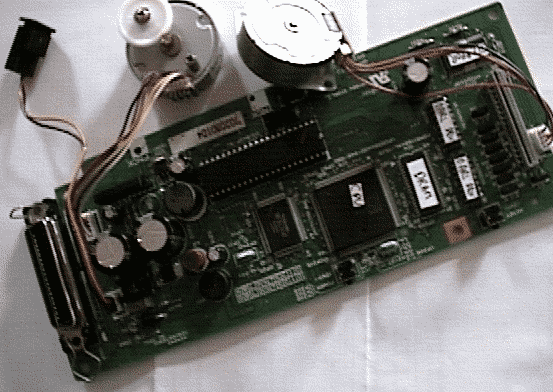

...but if you really want good cheap robot guts, try an old bubblejet.

You know, the kind where it costs half as much to replace the ink cartridge

as the entire unit costs. This is the circuitboard from a Cannon BJC240.

It's got two stepper motors with driver circuits all wired up to a couple

small CPUs that are running off some RAM and a ROM that is in a

removable socket. There are three phototransistors (the third is on

the head tape connector which is not shown), two buttons, a beeper, a LED,

and of course a parrallel port connector. This model runs off a wall wart

so the mainboard takes 13.5V DC, which is then charge-pumped to 27V to drive

the steppers. AC models will have a second AC convertor board and will expect

the 27V and a lower level logic supply to be provided -- so go for the

wall-wart models as they will be much easier to construct a battery for.

...but if you really want good cheap robot guts, try an old bubblejet.

You know, the kind where it costs half as much to replace the ink cartridge

as the entire unit costs. This is the circuitboard from a Cannon BJC240.

It's got two stepper motors with driver circuits all wired up to a couple

small CPUs that are running off some RAM and a ROM that is in a

removable socket. There are three phototransistors (the third is on

the head tape connector which is not shown), two buttons, a beeper, a LED,

and of course a parrallel port connector. This model runs off a wall wart

so the mainboard takes 13.5V DC, which is then charge-pumped to 27V to drive

the steppers. AC models will have a second AC convertor board and will expect

the 27V and a lower level logic supply to be provided -- so go for the

wall-wart models as they will be much easier to construct a battery for.

Of course you'll need docs for the two CPU's, a compatible PROM + programmer

(or maybe a gate array could be constructed to convince the unit to load

software into RAM through the parrallel port) and you'll likely have to

rewrite the stepper motor driver for one of the motors since that seems to be

done in software -- there's only one discrete controller onboard. But what's

a hobby without its challenges?

What you can expect to find inside some common disposable cigarette lighters:

springs, wheels, flints, tubes, and valves. On the left is the good old

Bic. If your objective is to light cigarettes, then accept no substitutes...

they are extremely reliable. However, if you want to use it for other stuff

later when you are done, get the Djeep shown in the middle. They aren't as

reliable as the Bic, but they aren't too bad and they have more interesting

guts. The valve comes out of the Djeep easily in one piece and looks sturdier.

Also, as shown, the Djeep's inside cavities are much bigger and with very

little effort can be pursuaded to fit AAA batteries. On the right is the

pernicious Ace lighter. Avoid it at all costs. I can't remember ever owning

one of these that didn't break well before all the fluid was gone. The flint

is half the diameter of the other two and frequently shatters against the

wheel, and the plastic in the valve arm tends to melt if used for anything

but a short duration.

Other people's adventures

- photos from inside a self-heating beverage can.

...many more to come.

...I've accidentally destroyed a good number of parts in my day :-)

Back to trash hacking main index

Once you've got the disk off you can get the circuit board off and you are

well on your way to the old-hat trick of hacking the floppy motor into some

sort of robotics device.

Once you've got the disk off you can get the circuit board off and you are

well on your way to the old-hat trick of hacking the floppy motor into some

sort of robotics device.

This shows just how easy that is with 3.5" floppies. Since the bottom row

of pins is grounded, just put a jumper across the inputs you want permanently

pulled low. For more on hacking floppies, see the

This shows just how easy that is with 3.5" floppies. Since the bottom row

of pins is grounded, just put a jumper across the inputs you want permanently

pulled low. For more on hacking floppies, see the

...but if you really want good cheap robot guts, try an old bubblejet.

You know, the kind where it costs half as much to replace the ink cartridge

as the entire unit costs. This is the circuitboard from a Cannon BJC240.

It's got two stepper motors with driver circuits all wired up to a couple

small CPUs that are running off some RAM and a ROM that is in a

removable socket. There are three phototransistors (the third is on

the head tape connector which is not shown), two buttons, a beeper, a LED,

and of course a parrallel port connector. This model runs off a wall wart

so the mainboard takes 13.5V DC, which is then charge-pumped to 27V to drive

the steppers. AC models will have a second AC convertor board and will expect

the 27V and a lower level logic supply to be provided -- so go for the

wall-wart models as they will be much easier to construct a battery for.

...but if you really want good cheap robot guts, try an old bubblejet.

You know, the kind where it costs half as much to replace the ink cartridge

as the entire unit costs. This is the circuitboard from a Cannon BJC240.

It's got two stepper motors with driver circuits all wired up to a couple

small CPUs that are running off some RAM and a ROM that is in a

removable socket. There are three phototransistors (the third is on

the head tape connector which is not shown), two buttons, a beeper, a LED,

and of course a parrallel port connector. This model runs off a wall wart

so the mainboard takes 13.5V DC, which is then charge-pumped to 27V to drive

the steppers. AC models will have a second AC convertor board and will expect

the 27V and a lower level logic supply to be provided -- so go for the

wall-wart models as they will be much easier to construct a battery for.