Back to trash-hacking main index

The Lock-plate Savonius

A Savonius is a drag-based VAWT that was invented yada yada yada,

blah blah blah, go here.

This is an interesting modular implementation for hobbyists or prototypers

using plastic soda bottles and those microwavable lock-together plastic

disposable plates you can get off the shelf at the supermarket for a few

bucks for a pack of 20.

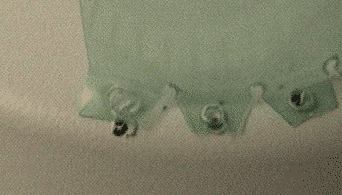

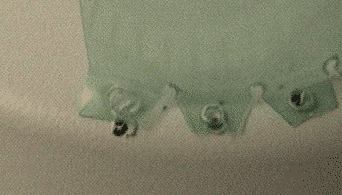

First I cut half of the outside off a bunch of soda bottles to act as the

blades. These sections already end up having a preference to curve at

about the right arc. I cut several vertical flaps in the top and bottom

to use to attach these parts to the plate. As much accuracy as can be

had is for the best here -- otherwise the unit ends up with quite a wobble

and imbalance. They are used in pairs, so I tried to match up pairs that

were as close to identical as possible.

Note before cutting the flaps I melted little holes through -- this

discourages tearing at the end of the cut. I of course was in a well

ventilated area at the time.

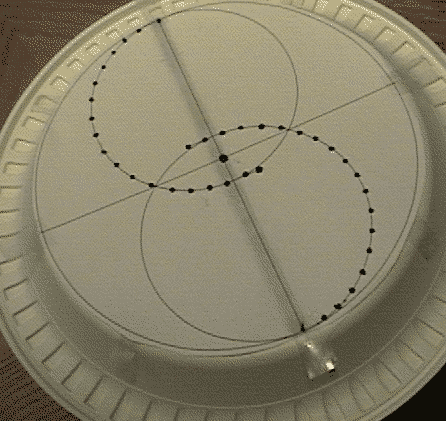

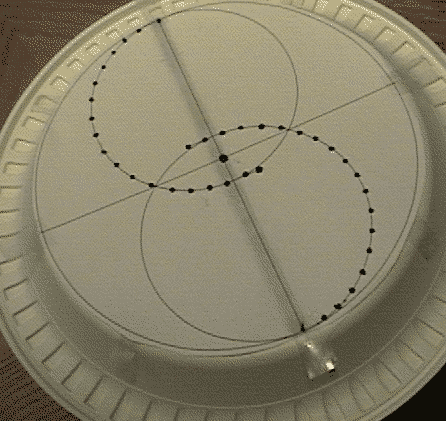

Next I printed out the following pattern on a laser printer -- which is

much easier than trying to use a ruler. I punched little holes through

the pattern so I could mark through it with a felt-tip pen, and then carefully

and precisely taped the pattern to one of the plates and marked it. Of course,

the pattern is flipped over in reverse for the plate on the opposing side.

In this case I'm trying out a variant blade with an air-channel in-between.

Some people claim these are better, but I've seen no solid data. A normal

blade would make a continuous "S" shape.

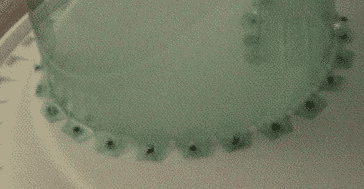

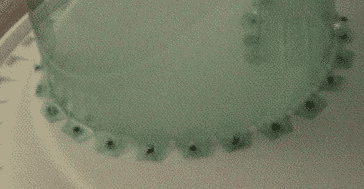

Then, again in a well ventilated area, I tempted fate and managed to use a

hot pen to punch through each tab while applying pressure to get the blades

flush against the plate. The plastic melts together and creates a binding

that's good enough to hold everything in place temporarily. This requires

some level of presence of mind and skill at not burning yourself or

accidentally melting into the unit while fussing around to get the blades

lined up with the pattern. The second plate is harder due to constrained

elbow-room -- err I suppose that's "knuckle-room" in this case. Having

translucent plates would have sure helped here.

Note after a bit of testing that the most of the stress ends up on the end

tab. I didn't have any, but if I did I'd put a pop-rivet in on each end tab.

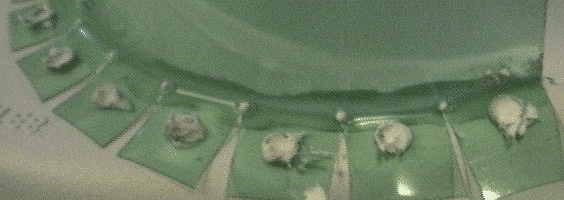

For a bit more lasting seal I used some silicon tub sealer forcing it through

the holes and squashing it on both sides. This also waterproofs the unit.

I also sealed along the bases of the blades to make them airtight. Not

that I expect that really is very critical.

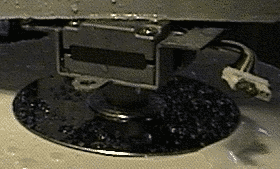

To construct the end-peices I codged together some flanges from 3.5" hard

drives (minus magnets.) (5.25" would be even better.) The plates are

peirced in the middle and sandwiched between two disk platters which holds

them tight and makes them more rigid. Less give here is good to prevent the

whole stack from bending too much. CDs may also be rigid enough to work here.

The genset attached to the top is a stepper motor from a bubblejet printer.

I think this one was from the traction feed, but the head motor would likely

work well, too.

Finally I whipped together a quicky temporary support frame for a test

deployment in the yard. Eventually I hope to build a shroud like Terra

Moya Aqua has been playing with to see how well it works. Plus something to

keep the water off the genset would be real nice...

With a two-stack design the unit could spin the motor when near a house-fan

on medium, and light a LED pretty brightly on high. The beauty of this

little trash hack is that the bladesets can be rearranged, rotated and stacked

as high as you can get to be stable. I haven't found the need yet to

permanantly glue the lock-plates together.

I found that due to the unavoidable 60-degree offset between consecutive

segments of a three-blade system it rocked too much in the middle section,

but a four-blade system with 180 degree turns or a 5-blade with 144 degree

turns might be more rigid. Likely anything beyond seven or eight will be

hard to keep straight inside the frame without putting some bracing spacers

between the plates.

Anyway I'm thinking I should have bought the red plates. Then I could

reverse the motor mount and add some red and green LEDs spinning on the unit

to make something suitably Christmas-like to have an excuse to put it on

the front lawn -- and then never take down.

Back to trash hacking main index